50000 ㎡

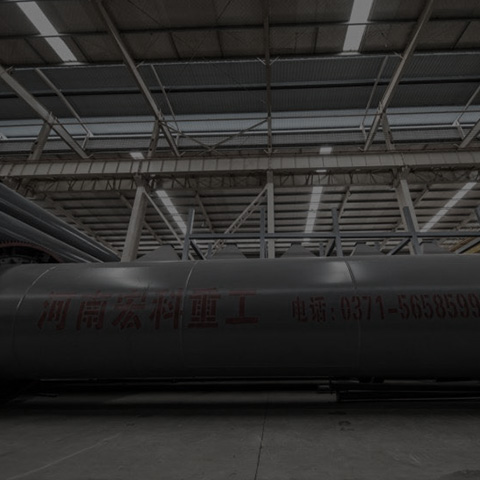

The company's headquarters covers an area of 50000 square meters.15000 ㎡

It has two 15000 square meters of standardized heavy industrial plants.600 +

More than 160 sets of various large and medium-sized gold processing, riveting and assembly equipment.Keep improving, treat customers honestly, and take zero mistakes as the management mechanism.

Quality first, service first is our service tenet, quality is the life of the enterprise, and customer satisfaction is our goal

Supply Rotary Kiln For 30 Years

Seeking truth from facts with good faith for the operation of the dedication, in conformity with principle of keeping improving, dealing honestly with customers, and taking zero fault as management mechanism, quality first and the best service are our service essentials.

Hongke Heavy Industries to participate in the 2024 Russian mining feast

Hongke Heavy Industries to participate in the 2024 Russian mining feast

How to Adjust the Smoke Control Ratio of Lime Kiln Rotary Kiln

How to Adjust the Smoke Control Ratio of Lime Kiln Rotary Kiln

Operation Essentials of Cyclone Dust Collector

Cyclone Dust Collector